China OEM Factory One-Stop Service Custom Casting/Machining Auto Parts for Bumper Bracket

Product Details

| Item | Truck Bump Bracket |

| Surface Preparation | Sand Blasting, Plating, Galvanized, Spray-Paint, Passivating, Polishing, Electrophoresis, Machining, etc. |

| Surface Treatment | Shot blasting/Polishing/Painting/Powder coating/Anodizing/Zinc plating/Nickel plating/blacking, etc. |

| Surface Roughness | Ra0.05∼Ra50, depends on Customer’s Requirements |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting tolerance | CT5-CT8 |

| Casting blank weight | 0.01kg-3000kg |

| Coating | Electrophoresis Coating |

| Machining | Lathing/Milling/Turning/Boring/Drillig/Tapping/Grinding, etc |

| Machining tolerance | 0.01mm |

| Design software/ formats | 3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T)/Soild Works/CAXA/Rhino/CATIA/SIMIO/ALIAS/ARENA/Unigraphics, etc |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Application | Heavy Truck, Light Truck, Commercial Vehicle , Forklift, Construction Machinery/Truck/Vehicle, Farm Vehicle/Machinery/Truck, Agriculture Machinery/Truck/Vehicle, Mining Machinery, etc. |

| Package | Bubble plastic bag/polybag/pallet/wooden case, etc. |

| Trademark | OEM |

| Origin | China |

| Loading Port | Qingdao Port |

| Annual Supply | 1000000 Pieces |

| Sample | Available |

| Sample production cycle | 30-45 Working days. |

| OEM/ODM service | Available |

About us

As a professional OEM/ODM casting/ forging/ machining factory, we offer variety of customizations for casting/ forging/ machining products, which can meet multifarious industrial demands. Our products including auto parts, car parts, truck parts, automobile/ automotive parts, heavy-duty truck parts, dump truck parts, vehicle parts, forklift parts, machinery/mechanical parts, machine parts, industrial parts, equipment parts, CNC machining parts, device parts, facility parts, engine/ motor parts, valve parts, pump parts, gearbox parts, farm/ agricultural machinery parts, farm/agricultural vehicle parts, combine harvester parts, tractor parts, trailer parts, mining machinery/ machine/ equipment/ truck/ vehicle parts, machine spare parts, hardware parts, etc. Among them truck bracket is one of our main products, mainly including engine bracket, steering gear bracket, leaf spring bracket, steering knuckle, bumper bracket, balanced suspension.

We stick to the business management philosophy that "Starting from the customer needs and ending with their satisfaction". We look forward to building a long, lasting and mutual beneficial business relationship with your esteemed company.

Product Description

Sand casting process uses the green sand or dry sand to make the molds for casting molten metals. Most of castings are produced by this old but new casting process. Sand casting is one of the most popular and simplest types of casting. Sand casting allows for smaller batches than permanent mold casting and at a very reasonable cost.

Due to its well-suited for complex geometries, sand casting process takes advantage of compact sand, refractory and recyclability to produce relatively less expensive molds with quick tooling development and design changes at a competitive cost. For some desired castings of huge size and weight, the sand casting process is the first choice we should think when we choose the suitable manufacturing methods.

The are several sand casting process based on different mold materials. At our Foundry, we can proceed the sand casting process by green sand casting, pre-coated resin sand casting and furan resin sand casting. The pre-coated resin sand casting is also called shell molding casting or shell casting. The shell casting process has much better surface for the finished castings.

In our high-tech facilities, we offer both automatic machine and manual molding operations in our resin sand casting processes. We can pour gray and ductile iron castings using our no-bake process up to 1 ton finished weight in gray iron castings and ductile iron castings, and up to 0.5 tons in steel castings and stainless steel castings.

What Metal and Alloys We Cast by Sand Casting

● Gray Cast Iron: HT150, HT200, HT250, HT300, HT350; EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300, EN-GJL-350; GG10, GG15, GG20, GG25, GG30,GG35, GG40.

● Ductile Cast Iron (Nodular Cast Iron): GGG40, GGG45, GGG50, GGG60, GGG70, GGG80; EN-GJS-400-18, EN-GJS-40-15, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2, EN-GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

● White iron, compacted graphite iron and malleable iron.

● Malleable Cast Iron.

● Carbon Steel, Alloy Steel.

● Aluminium and Its Alloys.

● Brass and Copper-based Alloys.

● Stainless Steel / Duplex Stainless Steel.

● Other Alloys as request or according to ASTM, SAE, AISI, GOST, DIN, EN, ISO, and GB.

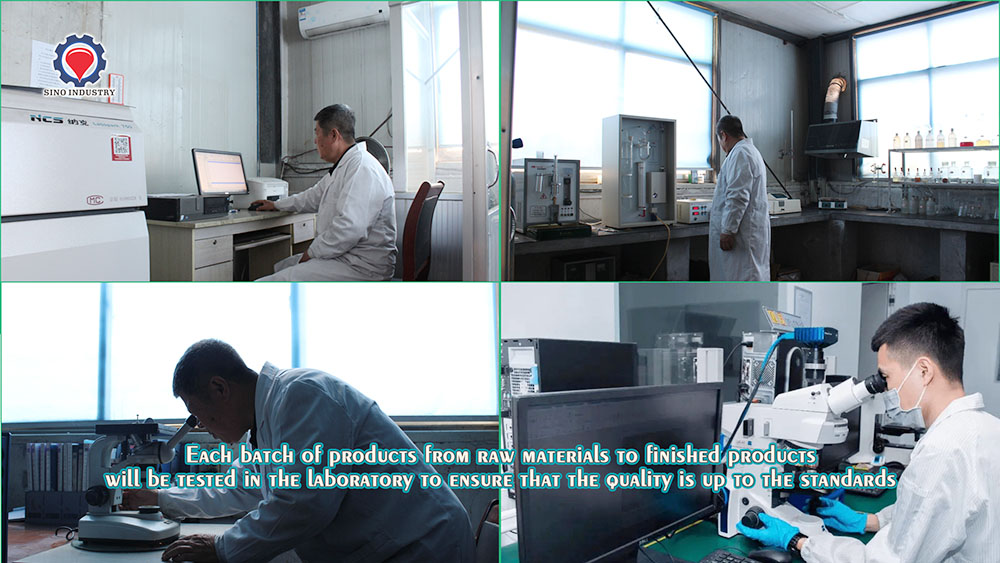

How We Inspect the Sand Castings

Our Spectrometer checks 20 chemical elements and metallurgical microscope produces high-resolution images 1,000 times magnified, and our cleanliness meter determines particle size and quantity to ensure materials meet or exceed the international standard. We use ultrasonic detectors to discover flaws, and have X-ray machines and accelerators that can scan castings with 200 mm maximum wall thickness.

Our factory has a full range of inspection capabilities in house, which include:

- Spectrographic and manual quantitative analysis

- Metallographic analysis

- Brinell, Rockwell and Vickers hardness inspection

- Mechanical property analysis

- Low and normal temperature impact testing

- Cleanliness inspection

- UT, MT and RT inspection

Steps of Sand Casting Process

1- Making Pattern

Patterns made of wood, resin (plastic) or aluminium could be used to produce during the casting. Generally, the costs of the aluminum patterns will be the highest, but it is the most suitable process if the customers need thousands of castings with higher dimensional tolerances and better surface quality.

2- Molding Process

The resin sand will be mixed by the sand treatment equipment, then shoot into the sand boxes (flasks). The molding workers will guarantee the sand can be filled to all positions, and make the sand as solid as possible.

3- Self-Hardening of Resin Sand Mold

After molding by workers, the sand is still loose. Then, the sand mold will be coated by a type of alcohols based coating, after burning, the resin sand mold will become very solid. This is why this casting process is called as hard mold casting process, also called as self-hardening sand mold.

4- Melting and Pouring

Just like the sand casting process, medium frequency electrical furnaces are used to melt irons for resin sand casting process.

5- Sand Blasting, Cleaning and Grinding

The shot blasting process is to remove the sand and oxides, then the workers will cut off the gating systems, and grind the gating positions and parting lines. Finally, the rough castings will be completed. If secondary processes like machining or surface treatment are needed, these complete castings will be taken to the next workshops.

What Facilities We Rely On for Sand Casting

We utilize the professional equipment to assemble the automatic casting production lines. We have two production lines for sand casting, the vertical automatic sand casting line and the horizontal automatic sand casting line. These highly organized equipment help us to produce the casting parts of high quality and big volume. These equipment can cast a diverse materials such as grey iron casting, ductile iron casting, carbon steel, alloy steel, stainless steel, aluminium and brass.

FAQ

Q: What's your MOQ?

A: Negotiable (depend on which products you need)

Q: What's your Payment terms?

A: 30% deposit, 70% balance payment before shipment.

Q: What payment method you accept?

A: Bank Tranfer, T/T, L/C, Credit Card, PayPal. Western Union.

Q: How do you control your quality?

A: All products were produced in high standards, and has passed component tests, unfinished tests and 100% products testing before delivery.

Q: How do you ship goods?

A: if you have shipping agent in China, we can send goods to your agent warehouse. If don't have agent, we will long cooperated shipping company, you can choose by DHL, Fedex, or UPS. or shipping by sea, we will give you several solutions to choose.

Q: Can we customized the length, size or with different materials?

A: Yes, we will try our best to meet your needs. We have special technology and skill to solve and handle special material, special structure, special defect and special processing.

Q: Can you produce the same product as mine if I provide you a sample?

A: Yes. Our engineers will draw a technical drawing for you according to your sample and thereafter send it to you for approval before mass production.

Q: Can you provide me free sample for checking quality?

A: It depends on the sample's cost, normally we can, but client has to pay the freight.